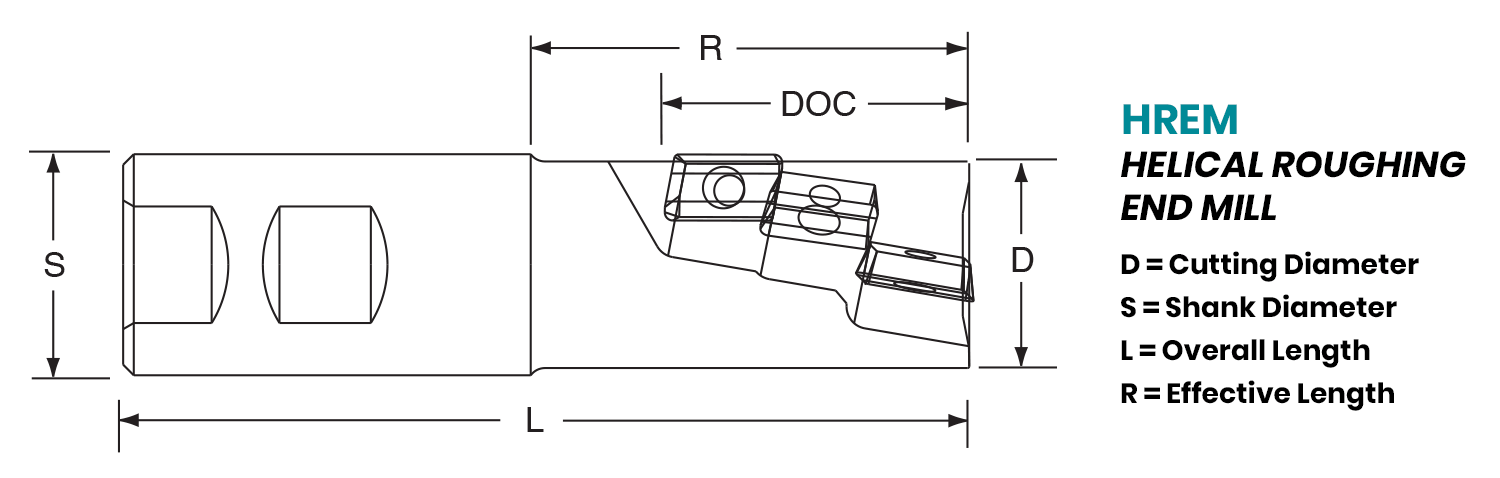

roughing end mill diagram

Diagram of typical Bridgeport style milling machine head. Well refer back to it a number of times as we go through the various exercises.

4 Flute End Mills For Hardened Steel End Mills Drills Frezycnc Eu

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plantsIt is an organic material a natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression.

. Indexable End Mill Bodies. Like on the roughing stand the steel is passed backwards and forwards through the mill. There are four versions of Haas amplifiers.

The diagram shows iron and carbons combined to form Fe-Fe 3 C at the 667C end of the diagram. Wide with a bottom inclined at from 3 to 4 inches of fall per foot. This is a practice called Tool Tuning.

Pdf 37MB free Isamu Nishida Hidenori Nakatsuji and Keiichi Shirase. Get the correct CHC. The left side of the diagram.

Indexable Ball End Mills. After rolling the strip is cooled to a controlled temperature on a run out table using banks of water sprays. Deep at the deepest end.

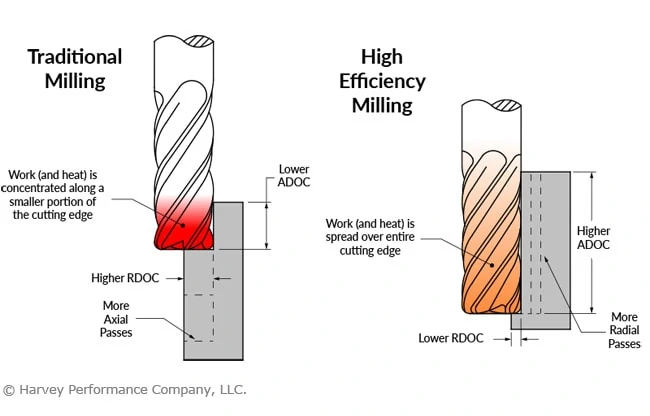

Roughing end mills quickly remove large amounts of material. Aerobic conditions are maintained by splashing diffusion and. Chamfer Mills.

B is the initial or roughing separatory cell. Mineral Processing Technology mineria procesamiento de minerales. The finishing train may have up to seven four-high rolling stands in tandem see Figure 4.

There was some P3 rotary products that were built with the air pressure sensor. The RPM for a l2-inch-diameter end mill machining aluminum revolves at 2400 RPM and the feed rate should be 24 inches per minute. Smart Amplifier assemblies are powered from the 320 VDC Bus from the Vector Drive assembly or Minimill Power Supply.

Automated Tool Path Generation for Roughing Using Flat Drill. It consists of a tank about 9 ft. Indexable Ball End Mills.

47 and 48 show the cell in detail. Try a roughing end mill. This is a reversing mill.

A Haas Responsibility B Your Responsibility 1 Haas Machine 2 Haas Machine Network Hardware 3 Your Server 4 Your computers. As well as trying shorter stickout which increases rigidity dont be afraid to try longer stickout. Monitoring of Vibrations in Free-Form Surface Processing Using Ball Nose End Mill Tools with Wireless Tool Holder Systems.

Indexable End Mill Bodies. It is 20 in. Indexable End Mill Bodies.

The spiral flute carries chips up and out of the hole as it cuts. If you want to run the unit it on a Classic Haas Control machine the following needs to be done. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations.

This is the normal end mill style. To make this site work properly we sometimes place small data files called cookies on your device. This deforms the material at point A on the diagram left hardening it and dulling the tool.

Long over all and 24 in. By default youre in Mill Mode. Wood is sometimes defined as only the secondary xylem in the stems of trees or it is defined more broadly to include the.

With downcut geometry the spiral is reversed so it pushes down instead of. It consists of a fixed bed of rocks coke gravel slag polyurethane foam sphagnum peat moss ceramic or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime to grow covering the bed of media. The tooth design allows for little to no vibration but leaves a rougher.

From new product information technical tutorials videos 3D CAD Models and community based forums Design World is the most useful online resource for the professional engineer. Transmission electron microscopy TEM is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The serrations can radically change the chatter frequency.

A trickling filter is a type of wastewater treatment system. Typically after leaving the plate mills roughing stand they are passed through a finishing stand. Shell Mill Bodies.

Use a coarse-tooth milling cutter for roughing cuts and a finer-toothed milling cutter for light cuts and finishing operations. Bring up G-Wizard G-Code Editor. At the shallow end and 45 in.

Indexable Ball End Mills. Most big websites do this too. Solutions manual fundamentals of modern manufacturing.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Changing stickout as little as 0100 can change the chatter frequency. The roughing section may comprise four or five four-high non-reversing stands or a single four-high reversing mill dependent on the mill design.

Fiddle with tool stickout. Pdf 65MB free. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a grid.

Associate membership to the IDM is for up-and-coming researchers fully committed to conducting their research in the IDM who fulfil certain criteria for 3-year terms which are renewable. Complete Indexable End Mill Kits. It may be built of either steel or wood preferably wood.

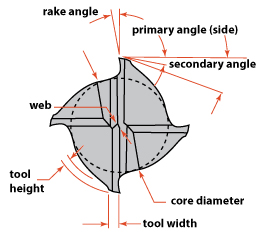

Get out the manual for your machine and find the diagram that shows how its coordinate system works. The sliding and biting behaviour leaves a poor finish on the material. Diagram of an End Mill.

These are probably the worst about splintering though with serious fine tuning and slower feeds and speeds you may be able to tame it a bit. Indexable Ball End Mills. Materials processes and systems second edition.

The Institute comprises 33 Full and 13 Associate Members with 12 Affiliate Members from departments within the University of Cape Town and 12 Adjunct Members based nationally or internationally. Indexable End Mill Bodies. 30A 1 45A 2 60A 3 and 90A 4.

An image is formed from the interaction of the electrons with the sample as the beam is transmitted through the specimen. Design World Online provides design engineers technical content and resources to help design products faster smarter and under budget. Chamfer Mills.

This kind of end mill utilizes a wavy tooth form cut on the periphery. Synonyms for control include management supervision administration charge direction guidance superintendence government regulation and running. The P12 and P15 rotary units were intended to run on NGC machines if the unit is connected to a Classic Haas Control the control will generate overheat alarms.

Make sure to leave the manual handy whether it is paper or online. Complete Indexable End Mill Kits. All four operate the same way.

Geometrical Parameters Of End Mills For Roughing And Finishing Part Download Scientific Diagram

Geometrical Parameters Of An Endmill Download Scientific Diagram

Basic End Mills Technical Information Msc Industrial Supply Co

Basic End Mills Technical Information Msc Industrial Supply Co

End Mill An Overview Sciencedirect Topics

Helical Roughing End Mills Hrem For 10mm Apet Xpet Inserts Page 1

Schematic Diagram Of The Side Milling Process Download Scientific Diagram

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

The Secret Mechanics Of High Feed End Mills In The Loupe

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

Roughing End Mills रफ ग ए ड म ल In Midc Bhosari Pune Orient Tools Id 3666888530

Solid Carbide End Milling Harvi I Te Four Flute End Mill For Roughing And Finishing Covering The Broadest Range Of Applications And Materials

Roughing End Mill Kyocera Unimerco

8 Ways You Re Killing Your End Mill In The Loupe

Endmill Design Basics Mastercut Tool Corp

End Mill An Overview Sciencedirect Topics